- One of the most frequently asked questions is which material is better and how methacrylate (or acrylic glass) differs from polycarbonate since they are very similar in appearance. Well, both one and the other are materials that can be adapted to our projects, the important thing when choosing between both is the differences in the properties of each material because they are not only in terms of the final finish, but they can also limit or expand the uses of the finished object. Let's look at some values below that will help you decide which material to choose.

- If we talk about impact resistance, compared to a more noble material such as glass, the differences are notable. Methacrylate or PMMA is 17 times

stronger, but not as strong against scratches, it must be kept away from metal elements. Up to 250 times more polycarbonate is practically unbreakable.

- When we talk about transparency index, there are also slight nuances. In fact, the battle here is won by PMMA, allowing 92.7% of light to pass through. Polycarbonate falls behind with an index of 88%.

Regarding temperature, the use of methacrylate is recommended up to 90 degrees. On the other hand, polycarbonate can resist temperatures of up to 120 degrees in continuous use.

Although it may not seem like it due to its resistance and previous factors, methacrylate is more rigid. This has advantages, but also disadvantages depending on the use to which it is intended. It must be considered that it is very light compared to glass and easy to manipulate, similar to wood. It weighs 60% less than glass.

Although it depends on the specific products, in general polycarbonate offers better resistance to some solvents and methacrylate to oils and slightly alkaline products.

Resistance to chemical agents and fire, one of the strengths of polycarbonate is that it retards the flame and does not emit toxic fumes, are other of its advantages compared to methacrylate, which is easy to burn although it does not produce any toxic gas either.

Regarding costs, historically polycarbonate was much more expensive but currently prices are very similar so the user must choose based on its properties and suitability for its application.

If we refer to ease of handling, methacrylate is easier to manipulate and cut, but above all to hot fold and glue. On the contrary, thin thicknesses of polycarbonate can be folded cold, being very useful to adapt to curved surfaces.

An important difference in favor of methacrylate is its resistance to aging. It can be used in outdoor applications without problems. It has greater resistance to damage that can be caused by the elements (protection against UV rays and chemicals), which is why it is considered the most resistant colorless plastic, whose passage of time does not lose its transparency or yellow the material. On the contrary, polycarbonate requires a special quality for outdoors with a UV barrier and its life will be more limited.

The methacrylate is certified for food use so it can be in contact with food.

Methacrylate is also a great thermal and acoustic insulator.

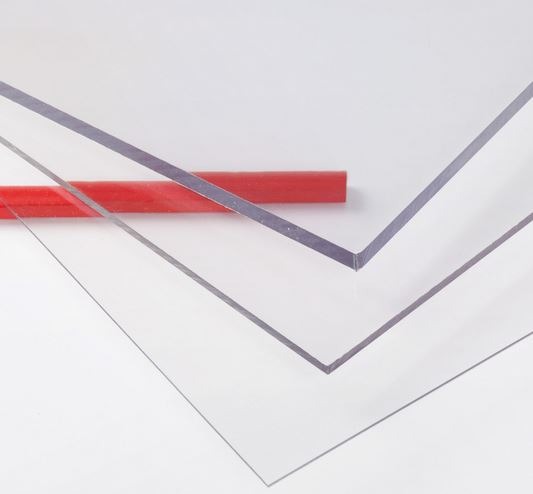

A good way to distinguish both materials with the naked eye will be by observing the edge of the plates. Methacrylate has a transparent edge while in the case of Polycarbonate, the edge is a darker, grayish color.

In conclusion, although there is a big difference between methacrylate and polycarbonate, the truth is that depending on the project to be carried out and its application, sometimes it will be better to use one or the other material.